I.Design

The design originates based on professional software and experienced staff. We execute a survey of the structure dimensions (by means of a measurement tool Leica 3D Disto). The design and dimensions of the structure are adapted to your needs and possible dimension changes originated during the execution

II.Production

Woodwork

Our modern CNC carpentry and joinery process line guarantees the highest quality of products (0.5 mm precision). We specialize in the production of:

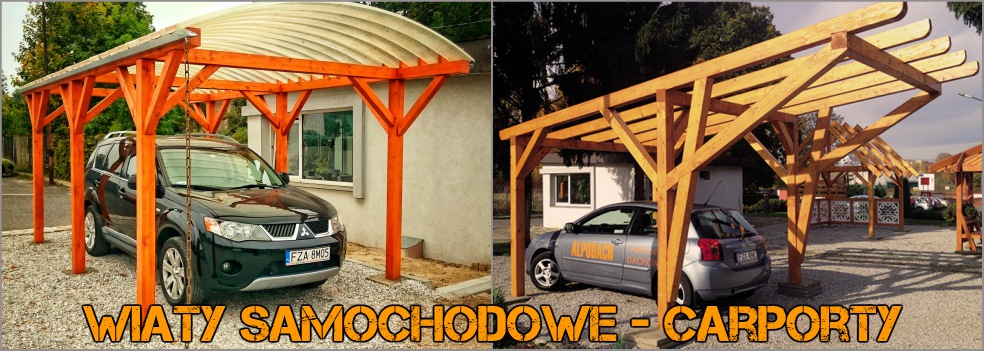

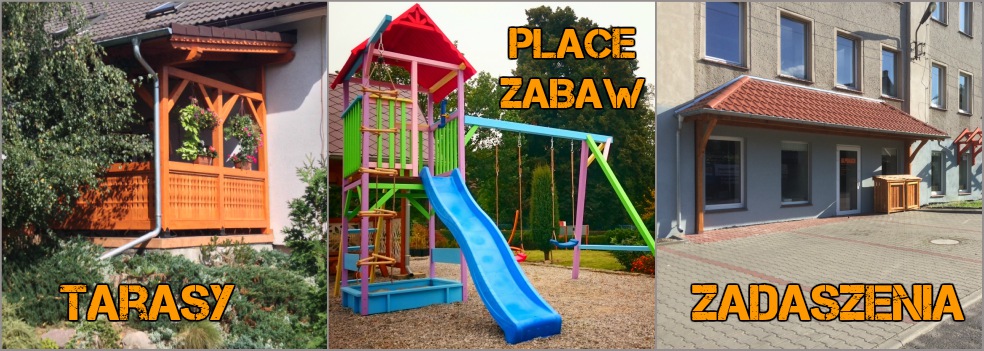

- Free standing utility objects (car ports, gazebos, play areas)

- Roof framing

- Objects to small architecture (ornamental towers, front entrance roofs, wells, boxes for waste segregation)

We create products according to documentation and orders of partner companies and individual customers (we will create practically every structure in accordance to your design).

Metalwork

We manufacture:

- Components for roof drainage and ventilation systems made of copper, zinc, aluminium, galvanized and stainless steel (we manufacture gutters of any length up to 6 running meters, waste-free)

- Accessories for ceramic, concrete and bituminous roof coverings

- Components for the construction of factory halls, gas stations and apartment buildings

- Metal roof coverings of small and large sizes

- Covering, edge and connecting elements of roofs

We execute individual designs based on a technical drawing.

III.Transport

We provide a specialized method of delivery of long carpentry elements to a building site as well as a modern unloading system (a forklift arrives together with structural members to the customer).

The assembly of an innovative roof framing, manufactured at Roof Factory Alpodach takes 1-2 working days. High quality of the components (0.5 mm precision – a traditional chisel has been replaced by modern cutters) allows for easy connections. The structure is manufactured without any foreign connecting elements (plate fasteners, screws, nails, etc.).

Examples of structures manufactured at Roof Factory Alpodach.